Extruded netting is amongst those things that are involved in our everyday life and yet remains a great unknown. Meshes are used in the most demanding industries, from automotive to clean energy generation, and can even be found inside the mattresses you sleep on.

Like many key industrial products, the role of a mesh is not to stand out by itself but to provide a certain function or enhance the performance of a complex product or system.

As a leading manufacturer of netting based solutions, Intermas designs, produces, and supplies a vast range of products used for a large variety of applications. Our meshes are manufactured through a continuous extrusion process where polymers are transformed into a mesh. Let us show you briefly the world of nets and their applications.

Fig 1. Diamond netting extrusion process

Different needs, different designs

Broadly speaking there are two types of netting according to its geometry: diamond and square. Each one of them has its unique features that can be summarized as follows:

A) Diamond netting

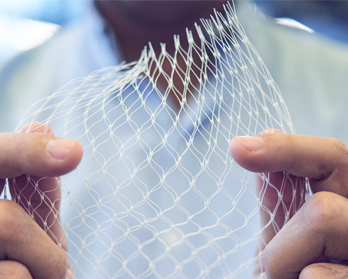

This rhombic mesh is produced using two counter-rotating dies. The result is two layers of parallel strands intersecting at a constant angle. The thickness of the top and bottom layers can be the same or different and the geometry of the filaments can be customized.

Fig 2. Various types of rhombic netting

B) Square Netting:

In this case, its structure follows either a square or rectangular pattern. One set of threads is parallel to the extrusion machine direction (MD), while the other set of threads is perpendicular (CD). Therefore, a square or rectangular hole pattern is created.

Fig 3. Square netting extrusion and examples

Once netting has been extruded, it can be post-processed to enhance some of its properties to produce what is known as oriented netting. This advanced manufacturing technique heats the net and stretches it in one or both directions to reduce its mass while significantly increasing its tensile strength. The most common name for these nets is BOP which stands for Bi-Oriented Polymer.

Fig 4. Bi-oriented netting (BOP)

Whatever your application is, we’ve got you covered!

Intermas’ extrusion process provides unparalleled versatility. Netting can be used either a standalone component or combined to enhance the properties of other materials such as plastic foils, membranes, technical papers, nonwoven or fiber-based materials.

So, which are the most common industrial applications for netting?

Drainage: fluids can flow through the open area of diamond meshes. The adequate combination of thickness, number of strands and angle provides the perfect flow-media for water, resins or any other liquids. Some example applications for this drainage feature can be found in reverse osmosis filtration and composite materials manufacturing.

Fig 5. Resin infusion nets used in wind blade manufacturing

Fig 6. Feed spacers used in membrane filtration for water purification

Support: rolled goods such as nonwoven materials and other flat or rolled goods such as foils are seldomly self-supportive so they require a backing element to keep a constant shape under the flow of fluids (air or liquids). Diamond nets are the ideal solution to support a pleated filter media within a filtration cartridge even under high-temperature operation.

Fig 7. PA6 and PBT nets used as pleat supports in high-temperature filtration

Reinforcement: rolled goods such as technical papers, foams and foils can take advantage of the additional tensile resistance provided by BOP nets.

Fig 8. BOP netting in mattress manufacturing

Protection: there are limitless possibilities when it comes to protect valuable items against scratches, chipping and other surface deterioration with Intermas extruded netting. Both diamond and square-shaped nets can act as an external protective and breathable layer in the most demanding environments.

Separation: packaging experts put their trust in our diamond, square and bioriented nets when it comes to find the best solution for goods separation, palletization and storage. No matter which kind of product needs to be stacked or separated, there is a net for it: machined parts, lubed elements, cans, dairy and other food products. Our high temperature resistant diamond trays are ideal for surface treatments and other demanding applications.

Fig 9. Diamond nets provide elasticity and adaptability to protect mechanical pieces

Lamination: the efficiency and performance of any of the above-described properties can be enhanced once netting is joined with one or several layers of other rolled goods to become a solidary working unit.

Fig 10. BOP netting used to enhance the mechanical properties of a paper-based packaging solution

Not all types of netting are ideal for all the previously stated applications. Here’s a summary table of the most common net structures used in each type of application.

Table 1. Suitable geometries for each application

Unable to find a solution for your application? Challenge us!

We understand that every project is different, no one knows your business like you do, sometimes a unique solution is required. At Intermas we know netting, we can create highly customized netting-based solutions to exceed your requirements. Contact one of our sales representatives to find the most suitable solution for your business.