Amongst the innumerable applications and industrial sectors where Intermas’ extruded plastic netting can be found, maybe one of the most surprising at first sight is wind blade manufacturing.

Extruded plastic netting, which is Intermas core business, is a key component in the Vacuum Infusion (VI) process used for wind blade manufacturing, acting as resin flow media. This VI process is also used in many other industries, such as marine, aerospace, transportation and military, to name a few. However, wind blade industry is the one with the highest growth rate in the past two decades.

A word on Vacuum Infusion

Vacuum Infusion is a manufacturing process through which a composite material, typically made of an epoxy (or polyester in some cases) resin matrix and a fiberglass reinforcement, is manufactured. After dry fiberglass is correctly placed over a wind blade mold, it needs to be impregnated by the resin and then cured (usually at room temperature). In order to have a controlled and even resin impregnation throughout the whole blade surface, while avoiding harmful gas emissions produced by the curing process of resins, blades are bagged with a polyamide film. Afterwards, air between the blade and the bag is extracted and vacuum is created. Finally, resin is pumped inside the bag, and vacuum pressure allows it to spread throughout the blade and impregnate glass fiber layers. Once the resin has hardened, vacuum bag and all auxiliary consumables used for the infusion process are removed and the piece further continues its curing process.

Extruded netting is one of the key consumables in this process. It is placed between glass fiber layers and the vacuum bag in order to create a thin permeable layer through which the resin can travel at higher speed and spread all along the blade surface in time, percolating into glass fibers. Without extruded netting acting as flow media in place, resin would travel too slowly and would harden before the whole fibers have been impregnated.

How did it get started?

As many other success stories within our Company, this one came right from a tight collaboration with a potential customer in the wind blade sector. This customer was willing to find an alternative to knitted nets used back in the late 90’s and early 2000’s in VI processes. As knitted and extruded netting have a similar structure, we though that it was worth giving it a try and see if one of our standard products at the time could perform at the same or maybe even at a higher level than knitted nets. From there, we would be able to propose a customized solution based on how well (or bad) our net performed compared to a knitted net.

Our surprise came when, after proposing a very common diamond polyethylene net for a first set of infusion tests, the results were surprisingly good. We had identified a solid foundation from where we could develop an adapted range of nets specifically designed for VI processes.

The road to specialization

As extruded netting started to take over knitted netting for wind blade VI processes, not only Intermas, but also our global competitors started to look into ways to improve infusion performance through new products. These specialty nets needed to be more technically complex and were engineered to provide a performance boost and overall cost reduction for wind blade manufacturers.

Each wind blade manufacturer takes its own approach on VI processes for their range of wind blades. Manufacturers find their own sweet spot between two key variables when working with extruded netting: infusion speed and wasted resin.

The graph above shows how infusion speed is related to wasted resin in Intermas Vacuum Infusion Nets range. It can be easily inferred that a faster infusion speed sacrifices more resin during the infusion process. With all this in mind, Intermas customizes each product according to customers’ needs, bringing the perfect compromise between production cycle time and raw material expenditure.

On one side, a fast infusion speed reduces the whole production cycle time, improving overall plant productivity, thus reducing workforce costs, which are very high in composite industries due to the lack of automatization in most parts of the production process.

On the other side, achieving the lowest possible resin consumption is key to keep raw materials costs in control. Epoxy and polyester resins are expensive products, and no manufacturer is willing to throw away resin that does not end up in the blade structure itself. On top of that, reducing the total amount of wasted resin in the process is key to help decrease the environmental impact associated with wind blade manufacturing.

Getting better through knowledge

Roughly 20 years have passed since Intermas first got involved in wind blade manufacturing as a supplier of one of the key consumables in Vacuum Infusion processes. Along the way we have managed to learn a lot about how our products perform. Production processes are notoriously different between blade manufacturers and, as understandable as it is, information is not easily shared by these players regarding technical data on infusion process set-ups and performance. So, in a way, we had to go our own way.

In 2016, Intermas partnered with a long-time trusted composites laboratory, a renowned specialist in composites. Our common goal was clear but not easily achievable: increase infusion speed while maintaining or even reducing wasted resin. For our customers, this goal would mean less expenditure on resin and shorter cycle times.

Intermas and its partner then started a long-term project which essentially consisted of 2 phases:

-

Phase 1: analyze our existing range of Vacuum Infusion nets and get to know more about each product’s performance. This would allow our technical sales team for a better decision making and advisory skills when dealing with new projects or when proposing cost-saving alternatives to our existing customers

-

Phase 2: dive deeper on how variations in different structural and geometrical parameters influence infusion speed and wasted resin values in each product. This would allow us to find the best way to fine tune each reference for the specific needs of every customer

This continuous work-in-progress has already yielded very useful data and results which have allowed us to keep improving our range of infusion nets. We are confident that our approach, based on focusing in what matters the most to the wind blade industry, will keep us ahead of our competition and will ultimately lead to an increase of efficiency and decrease of overall waste in wind blade production. In Intermas we believe that our humble contribution is making a difference towards a more sustainable and greener energy production around the world.

Ready for tomorrow’s challenges

As wind blade production around the world ramped up at jaw-dropping growth rates, manufacturers gradually shifted towards new purchasing and supply chain strategies. These approaches have recently reached a point of certain maturity, and the reigning trend is that manufacturers lean more than ever on their suppliers and other third parties for fiber, core materials and consumables manipulation.

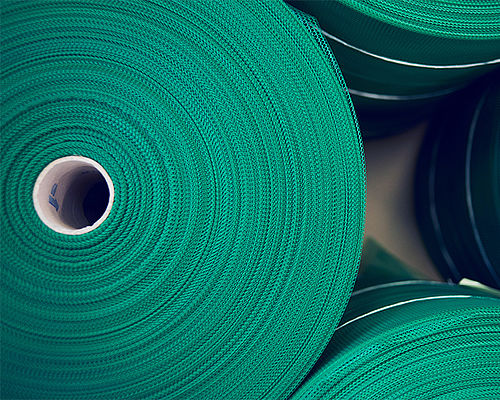

In the case of infusion netting, Intermas has successfully adapted to multiple customization requests. As of today, we are able to produce in-house infusion netting rolls from 7cm to 2,4m wide. We also customize roll lengths for each wind blade model for our customers, delivering specific roll lengths for each single project. These two factors provide significant reduction in wasted product and help to reduce the overall layout process times.

Customer quality requirements are now stricter than ever. In these regards, it has become key to implement rigid internal protocols in terms of production process and quality control, along with intensive and continuous production staff training. All these actions have enabled Intermas Group to excel in product quality and stability. Last but not least, training in our flow media products goes from production to post-sales assistance, and has been highly praised by our customers.

Another critical need for wind blade manufacturers is flexibility in deliveries and adaptative production plans which may not stick to initial forecasts. Yearly consumption is not distributed evenly over each month, and some months can witness a peak demand that can be as high as twice the average. This situation constitutes a great challenge for Intermas Production and Supply Chain teams, even more when considering that Intermas infusion products are delivered worldwide. But it also means that our production capacity and supply chain structure is ready for an upcoming sustained growth. We have proven to ourselves and more importantly to our customers that we are ready for a brighter, cleaner future.

For more information on our range of products for Vacuum Infusion processes, you can check our website, or contact our technical sales team.